Balanced Flow Meter (BFM) was initially invented by a NASA subsidiary company A+FlowTek, to measure the liquid fuel of the main engines on space shuttles. This invention was Inducted in the NASA invention hall-of-fame. Since 2007, Shanghai Keyontechs have been exclusively authorized by A+FlowTek of manufacture and sales of the BFM.

Shanghai Keyontechs has inherited the legacy of NSAS and continued the development of the Balanced Flow Meter Series. In 2022, Keyontechs launched the latest and most advanced DP flow meter: Balanced Venturi Flow Meter (BVFM), aiming to break through the limitations commonly found in traditional differential pressure flow meters.

A+X Balanced Venturi Flow Meter combines the functions of the flow conditioner and throttling sensor to meet measurement needs in various conditions. It has short straight pipe requirement, high accuracy, low pressure loss and long service life. To this day, over 100,000 units of BFM have been installed globally to more than 40 different industries.

Key Features

● High measurement accuracy: The multi-hole structure design balances the flow field, reduces vortices, vibrations and signal noise, improving the flow field stability. The accuracy is ±0.25-0.5% with actual flow calibration.

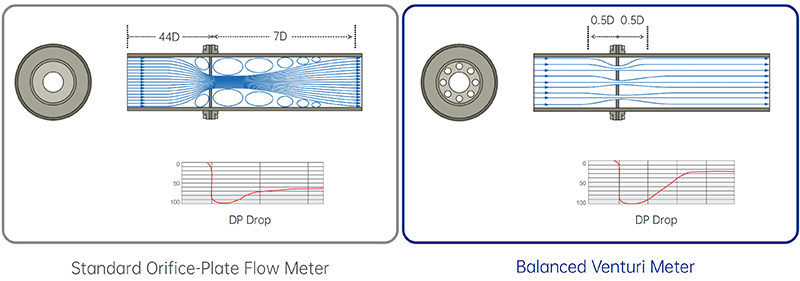

● Low straight run requirement: The flow element serves as a conditioner, adjusts the uneven flow to uniform flow, shortening the straight run requirement to 0.5D upstream- 2D downstream.

● Low permanent pressure loss: The BVFM reduces vortices and turbulent friction, lowering kinetic energy loss. Pressure loss is 70% less than traditional Orifice, close to Venturi tube.

● Wide turndown ratio: Standard measurement range ratio is 10:1, can reach to 30:1-50:1 with multiple transmitters.

● Good repeatability and stability: The repeatability of the balanced flow sensor is ±0.1%. Multiple flow holes evenly distribute force. No moving parts results in 5-10 times longer life than traditional orifice.

● Resistant to dirt and clogging: Multi-hole symmetrical design reduces turbulence, minimizes dead zones, allows dirty media to pass, reduces clogging.

● Wide measurement range: The BVFM covers flow velocity from minimum to sonic speed, with Reynolds number range from below 200 to above 10^7.

● Energy and cost saving: The overall energy and cost saved by BVFM from its low pressure loss, short pipe run, high process control accuracy , and long service life

● Application scope: The BVFM can satisfy almost all the insdutrial measurement applications. It can measure gas-liquid two-phase, corrosive, slurry or fluid with solid particles. The A+X Balanced Venturi Flow Meter can also measure bidirectional flow.

Process Connection | Flanged, Welded, Wafered |

Size | DN25-DN2000 |

Reynolds Number | 8000<Re<107 |

Temperature | -253~1000°C |

Pressure | ≤42M Pa (CL2500 lb ) |

Uncertainty Degree | ±0.25%-±0.5% |

Turndown Ratio | 10:1-50:1 |

Repeatability | ±0.1% |

Flange Standard | ANSI B16.5, HG/T20592,HG/T20615 |

Straight Pipe | Upstream2D + Downstream2D |

β Value | 0.25-0.75 |

Fluid | Liquid, Gas, Vapor |

Permanent Pressure Loss | 15% DP |

Copyright © 2025 Keyontechs Co.,Ltd.