A+X orifice plates are designed and manufactured in accordance with ISO 5167-2. It is the most commonly used DP flowmeter.

Product Highlights

● The standardized orifice geometry ensures measurement accuracy.

● A reliable and widely used differential pressure flowmeter globally.

● Precision machining ensures the quality of the orifice flowmeter.

● Simple and robust structure, no moving parts.

Standard Specifications

● Pipe size: 2 "~120" (DN 50mm~1000 mm)

● β value range: (0.1≤ β ≤0.75)

● Reynolds number range: ReD ≥5000, and ReD ≥170β2D

● Uncertainty: according to ISO5167-2:2003, the uncertainty is ±0.75%

● Accuracy: up to ±0.5%

● Repeatability: ≤0.15%

● Permanent pressure loss: 42%~99% of differential pressure

● Operating temperature: -196°C≤ T ≤700°C

● Working pressure: up to CL2500 (42MPa)

● Straight run requirement: before 6D-44D, after 4D-8D, depending on β

● Pressure tapping specifications: 1/4" NPT or PSW; 1/2" NPT or PSW; 1" or 2" flanged tapping

● Standard material: 304, 316, 321

● Customized materials: Hastelloy C-276, Monel 400, Inconel, more available upon request.

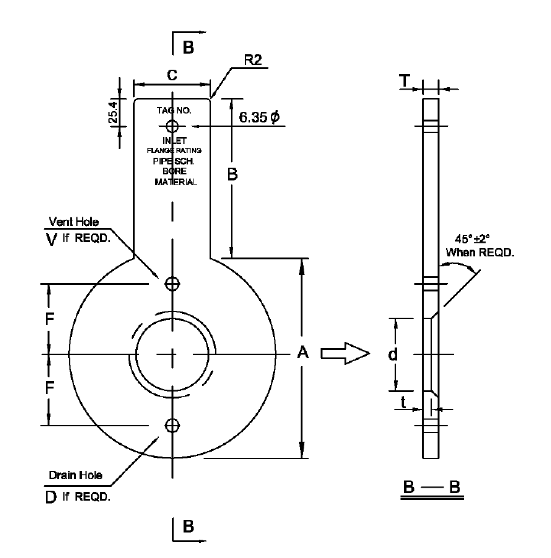

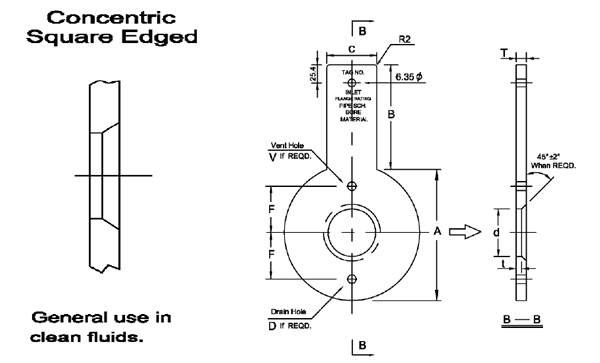

Orifice Plate Flow Element

Orifice throttling element is the core measuring element of orifice flowmeter

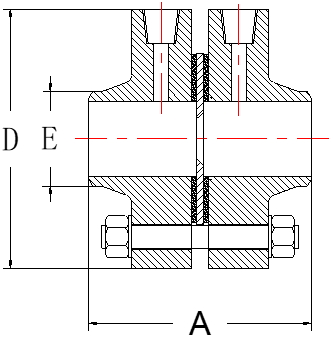

Wafered Type AOFF

● The orifice throttling device is wafered with orifice flange and its accessories. The orifice throttling device can have flange tapping or corner tapping.

● Most consistent with the traditional structure.

● Avoid the problem of mismatch between flange and orifice element design on site.

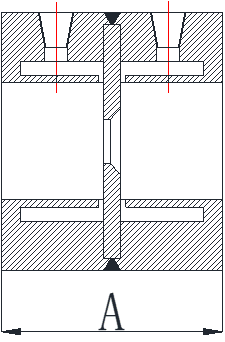

Pipe Segmented Type AOHF

● The orifice throttling device is connected with the pipe segment. The pressure tapping can be done by ring chamber.

● The pressure equalizing ring design reduces the influence of the flow field on the differential pressure signal, and the measurement accuracy is higher.

● High measurement accuracy.

● Flange connection on site.

Copyright © 2025 Keyontechs Co.,Ltd.