GENERAL DESCRIPTION

● AEMG-I Series is an insertion type electromagnetic flowmeter

● It is ideal for conductive liquids, widely used for drinking water, waste water, food & beverage, pulp & paper and many other industrial fluids.

● Two-Way measurement function.

● Display in instantaneous flow and accumulated flow.

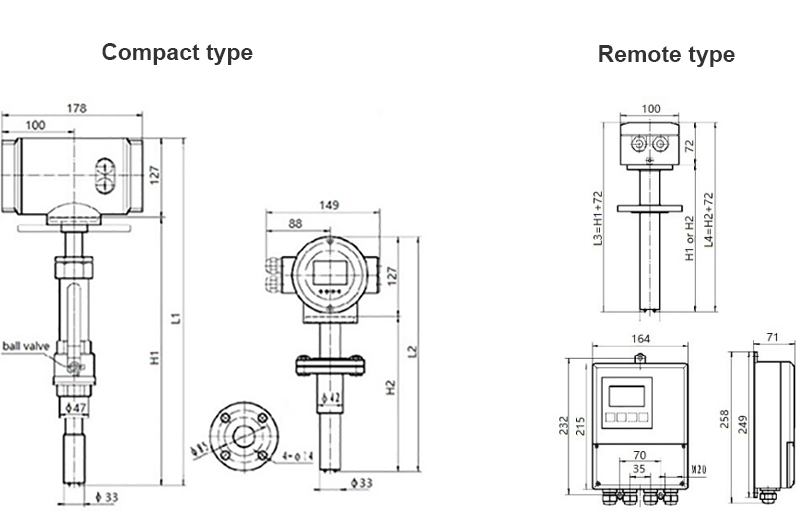

● Integral or remote display.

MAIN SPECIFICATIONS

Size | DN300 to DN3000 | Conductivity | More than 20μS/cm |

Material | Protection tube: SS304 Mounting base: SS304 Screw: SS304 Ball valve: SS304 | Electrode | 316L Stainless Steel Titanium Tantalum Hastelloy B Hastelloy C Tungsten Carbide Platinum |

Mounting | Compact or Remote | Temperature | -20 ~ +120℃ |

Process Connection | Thread Flange, DIN/ANSI/JIS | Accuracy | 2.5% value of reading |

Installation | Direct insert to the pipe Insert with Ball Valve | Ambient temp. | -20 ~ +60℃ |

Explosion | Ex db ib mb llC T6 Gb | Measuring range | 0.5 - 3m/s |

Ingress Protection | IP65 (standard) IP68 can be optional for sensor | Pressure range | 0.6MPa - 1.6MPa |

FLOW RANGE

The comparison table of pipe size, average velocity (m/s), volume flow (m3/h) for normal size

| 0.5(m/s) | 1.0(m/s) | 1.5(m/s) | 2.0(m/s) | 2.5(m/s) | 3.0(m/s) |

300 | 127.2 | 254.4 | 381.6 | 508.8 | 636.0 | 763.2 |

350 | 173.1 | 346.2 | 519.3 | 692.4 | 865.5 | 1038.6 |

400 | 226.1 | 452.2 | 678.3 | 904.4 | 1130.5 | 1356.6 |

450 | 286.2 | 572.3 | 858.3 | 1144.6 | 1430.8 | 2574.9 |

500 | 353.3 | 706.5 | 1059.8 | 1413.2 | 1766.5 | 2119.8 |

600 | 508.7 | 1017.0 | 1526.0 | 2034.0 | 2544.0 | 3052.0 |

700 | 682.4 | 1385.0 | 2047.0 | 2730.0 | 3412.0 | 4094.0 |

800 | 904.3 | 1808.0 | 2713.0 | 3617.0 | 4522.0 | 5126.0 |

900 | 1145.0 | 2290.0 | 3435.0 | 4580.0 | 5725.0 | 6870.0 |

1000 | 1413.0 | 2826.0 | 4239.0 | 5652.0 | 7065.0 | 8478.0 |

1200 | 2034.0 | 4068.0 | 6102.0 | 8136.0 | 10170.0 | |

1400 | 2770.0 | 5540.0 | 8310.0 | 11080.0 | 13850.0 |

STANDARD SPECIFICATION

H1(mm) | L1(mm) | L3(mm) | Size |

500 | 627 | 572 | DN300 – DN1000 |

90 | 1027 | 972 | DN1200 – DN3000 |

H2(mm) | L2(mm) | L4(mm) | Size |

213 | 340 | 285 | DN300 – DN1000 |

253 | 380 | 325 | DN1200 – DN3000 |

MODEL SELECTION

AEMG - | □□□ | □ | □□ | □ | □ | □ | □ | □ | □ | □ | □ | □ | □ | □ |

[1] | [2] | [3] | [4] | [5] | [6] | [7] | [8] | [9] | [10] | [11] | [12] | [13] | [14] |

[1] | Nominal Diameter(mm)/ [inches] | [7] | Grounding and Lining Protection | |||||

002 | 032 [1¼] | 250 [10”] | 900 [36”] | -0 | Flange or body ground (10...2400) | |||

003 | 040 [1½] | 300 [12”] | 102 [40”] | -1 | Earth ring (10...250) | |||

004 | 050 [2”] | 350 [14”] | 122 [48”] | -2 | Ground electrode (25...2400) | |||

006 | 065 [2½] | 400 [16”] | 142 [56”] | -3 | Inlet protection ring (50...300) | |||

008 | 080 [3”] | 400 [16”] | 162 [64”] | [8] | Max. Process Temperature | |||

010 | 100 [4”] | 500 [20”] | 182 [72”] | A | ≤80℃ (All Linings) | |||

015 [½”] | 125 [5”] | 600 [24”] | 202 [80”] | B | ≤120℃ (PTFE、PFA、F46) | |||

020 [¾”] | 150 [6”] | 700 [28”] | 222 [88”] | C | ≤180℃ (PTFE、PFA) | |||

025[1’’] | 200 [8”] | 800 [32”] | 242 [96”] | [9] | Configuration - sensor/transmitter | |||

C | Compact (10...1000) | |||||||

[2] | Device Type | R | Remote (with 10m cable) | |||||

F | Flange | [10] | Environmental Protection Class | |||||

I | Insertion | 5 | IP65 | |||||

W | Wafer | 7 | IP67 | |||||

K | Clamp | 8 | IP68(Remote Type Only) | |||||

[3] | Flange Rating | [11] | Power Supply | |||||

06 | 0.6MPa (700...2400) | -A | (85-265)VAC/(45-63)Hz | |||||

10 | 1.0MPa (200...1200) | -D | (9-32)VDC | |||||

16 | 1.6MPa (10...600) | -B | 3.6VDC lithium battery | |||||

20 | ANSI 150 (15...600) | -C | 3.6VDC lithium battery +(85-265)VAC/(45-63)Hz | |||||

25 | 2.5MPa (10...600)

| |||||||

40 | 4.0MPa (10...150) | -F | 3.6VDC lithium battery +(9-32)VDC | |||||

50 | ANSI 300 (15...600) | |||||||

99 | Special | [12] | Output and Input | |||||

[4] | Flange and Shell Material | B | Basic Configuration (current, pulse and contact outputs) | |||||

0 | Carbon steel | |||||||

4 | 304 Stainless Steel | M | Basic Configuration+MODBUS | |||||

6 | 316 Stainless Steel | H | Basic Configuration+HART | |||||

9 | Special | P | Basic Configuration+Profibus-DP | |||||

[5] | Lining Material | [13] | Calibration Specification | |||||

1 | Soft Neoprene (≤2400) | 1 | 3 point, 0.5% accuracy | |||||

2 | Hard Neoprene (≤2400) | 2 | 3 point, 0.2% accuracy | |||||

3 | PTFE (≤2400) | 3 | 5 point, 0.5% accuracy | |||||

4 | Polyurethane (≤300) | T | Other | |||||

5 | PFA (≤250) | [14] | Special Functions | |||||

6 | F46 (≤250) | /B | None | |||||

7 | Ceramics (≤250) | /T | Power off timer | |||||

8 | ETFE (≤600) | /Q | Quantitative control | |||||

9 | Nylon (≤2400,Insertion type only) | /H | Hourly accumulation | |||||

[6] | Electrode Material | /J | Relay output | |||||

1 | 316L Stainless Steel | /S | High frequency slurry | |||||

2 | Hastelloy C-22 | /G | GPRS | |||||

3 | Hastelloy B-10 | /N | NB-IoT | |||||

4 | titanium | /L | Ultra-low temperature | |||||

5 | tantalum | /P | Pressure sensor | |||||

6 | platinum/iridium Alloy | /K | RTD | |||||

7 | Tungsten Coated Stainless Steel | /C | Conductivity Sensor | |||||

8 | Ceramic | |||||||

E.G. | Ordering Code: AEMG-300I10491-0AC5-AMT/B | |||||||

A+K electromagnetic flowmeter; DN300, Insertion type, 1.0MPa, 304 Stainless steel flange and shell, Nylon lining, 316L stainless steel electrode; Body grounding, Max. Process Temperaturee≤80℃, Compact–sensor/transmitter, Ingress Protection Class IP65; AC power supply, Basic configuration+MODBUS, 3 point, 2.5% accuracy. | ||||||||

Copyright © 2025 Keyontechs Co.,Ltd.