Based on Faraday's Law, Electromagnetic Flow Meters measure conductive liquids.

Electromagnetic Overview:

The electromagnetic flowmeter (EMF) is a flow measurement instrument designed based on Faraday's Law of Electromagnetic Induction, primarily used to measure the volumetric flow rate of conductive liquids. Its core advantages lie in non-invasive measurement, zero pressure loss, and strong adaptability to fluid physical properties (e.g., temperature, pressure, viscosity). It is widely applied in industrial process control, water treatment, chemical, food, pharmaceutical, and other industries.

Working Principle

The electromagnetic flowmeter operates based on Faraday's Law of Electromagnetic Induction, which states that a conductor moving through a magnetic field generates an electromotive force (EMF). Key implementation steps:

1.Magnetic Field Generation: A pair of excitation coils in the flowmeter's measurement tube generates a uniform magnetic field perpendicular to the fluid flow direction when energized.

2. Conductive Fluid Flow: The measured liquid (with conductivity ≥5 μS/cm) flows through the magnetic field, acting as a conductor cutting magnetic lines.

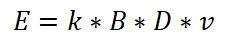

3. EMF Generation: Charged ions in the fluid induce an EMF (E) between electrodes perpendicular to both the magnetic field and flow direction:

-k: Instrument constant

-B: Magnetic flux density

-D: Pipe inner diameter

-v: Average fluid velocity

4. Flow Calculation: By measuring (E) and combining it with the pipe’s cross-sectional area , the flow rate is calculated as (Q = v*A).

Core Components

1. Measurement Tube: Lined with insulating materials (e.g., PTFE, rubber) to prevent electrode shorting and resist corrosion.

2. Electrodes: Material selection (e.g., Hastelloy, titanium, platinum-iridium) depends on fluid properties.

3. Excitation Coils: Generate uniform magnetic fields, critical for accuracy.

4. Transmitter: Processes electrode signals into standard outputs (4–20 mA or digital signals).

Advantages

- No moving parts, high reliability, low maintenance.

- Wide measurement range (turndown ratio up to 100:1).

- Unaffected by fluid density, viscosity, temperature, or pressure.

- Bidirectional flow measurement with zero pressure loss.

Limitations

- Requires conductive liquids (≥5 μS/cm); unsuitable for gases, oils, or pure water.

- Installation demands full-pipe flow and straight pipe sections (typically 5D upstream, 3D downstream).

- Higher cost, especially for large-diameter pipes.

Copyright © 2025 Keyontechs Co.,Ltd.