ОБЩЕЕ ОПИСАНИЕ

● Серия AEMG-F представляет собой электромагнитный расходомер фланцевого типа.

● Он идеально подходит для токопроводящих жидкостей, широко используется для питьевой воды, сточных вод, продуктов питания и напитков, целлюлозно-бумажной промышленности и многих других промышленных жидкостей.

● Функция двухстороннего измерения.

● Отображение мгновенного и накопленного расхода.

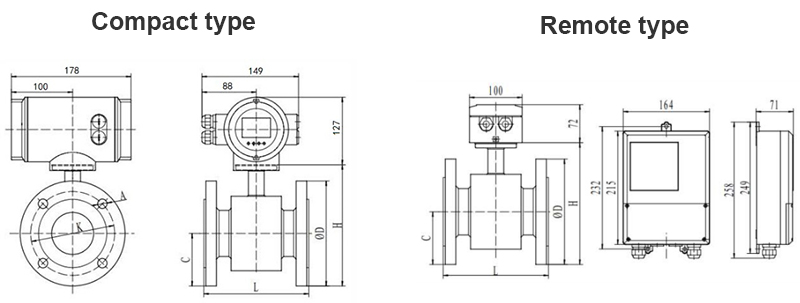

● Встроенный или выносной дисплей.

MAIN SPECIFICATIONS

Measuring range | 0.3-12m/s | Conductivity | More than 5μS/cm |

Material | Measuring tube: SS304(standard) Flange: Carbon steel (Standard) SS304/316/316L (Option) Coil housing: Carbon steel (standard) SS304/316/316L (Option) | Electrode | 316L Stainless Steel Titanium Tantalum Hastelloy B Hastelloy C Tungsten Carbide Platinu |

Liner | Neoprene (DN40-DN2400) PTFE (DN10-DN1000) F46 (DN6-DN500) Polyurethane (DN10-DN500) PFA (DN10-DN500) | Temperature | -20~+60℃ (Neoprene) -20~+120℃ (PTFE) -40~+140℃ (F46) -10~+60℃ (Polyurethane) -40~+180℃ (PFA) |

Ingress Protection | IP65 (standard) IP68 can be optional for sensor | Flange Type | DIN PN10/PN16/PN25/PN40 ANSI 150# / ANSI 300# / ANSI 600# JIS 10K / JIS 20K / JIS 30K |

Explosion | Ex db ib mb llC T6 Gb | Ambient temp. | -20~+60℃ |

Grounding electrode | SS316L electrode (standard configuration) | Max. Pressure | 420bar |

FLOW RANGE

| 0.3 | 1 | 2 | 3 | 4 | 5 | 12 |

6 | 0.0300 | 0.1017 | 0.2034 | 0.3051 | 0.4068 | 0.5085 | 1.2204 |

10 | 0.0840 | 0.2826 | 0.5652 | 0.8478 | 1.1304 | 1.4130 | 3.3912 |

15 | 0.1920 | 0.6362 | 1.2723 | 1.9085 | 2.5447 | 3.1809 | 7.6341 |

20 | 0.3390 | 0.131 | 2.2619 | 3.3929 | 4.5239 | 5.6549 | 13.5717 |

25 | 0.5310 | 1.7671 | 3.5343 | 5.3014 | 7.0686 | 8.8357 | 21.2058 |

32 | 0.8682 | 2.8938 | 5.7876 | 8.6814 | 11.5752 | 14.4690 | 34.7256 |

| 40 | 1.3560 | 4.5239 | 9.0478 | 13.5717 | 18.0956 | 22.6195 | 54.2868 |

50 | 2.1210 | 7.0686 | 14.1372 | 21.2058 | 28.2743 | 35.3429 | 84.8229 |

65 | 3.5850 | 11.9459 | 23.8918 | 35.8337 | 47.7836 | 59.7295 | 143.3508 |

80 | 5.4300 | 18.0956 | 36.1911 | 54.2867 | 72.3823 | 90.4779 | 217.1469 |

100 | 8.4810 | 28.2743 | 56.5487 | 84.8230 | 113.0973 | 141.3717 | 339.2919 |

150 | 19.0860 | 63.6173 | 127.2345 | 190.8518 | 254.4690 | 318.0863 | 763.4070 |

200 | 33.9300 | 113.0973 | 226.1947 | 339.2920 | 452.3893 | 565.4867 | 1357.1679 |

250 | 53.0130 | 176.7146 | 353.4292 | 530.1438 | 706.8583 | 883.5729 | 2120.5749 |

300 | 76.3410 | 254.469 | 508.9380 | 763.4070 | 1017.8760 | 1272.3450 | 3053.6280 |

350 | 103.9080 | 346.3606 | 692.7212 | 1039.0818 | 1385.4424 | 1731.8030 | 4156.3272 |

400 | 135.7170 | 452.3893 | 904.7787 | 1357.1680 | 1809.5574 | 2261.9467 | 5428.6722 |

450 | 171.7680 | 572.5553 | 1145.1105 | 1717.6658 | 2290.2210 | 2862.7763 | 6870.6630 |

500 | 212.0580 | 706.8583 | 1413.7167 | 2120.5750 | 2827.4334 | 3534.2917 | 8482.3002 |

600 | 305.3640 | 1017.876 | 2035.7520 | 3053.6281 | 4071.5041 | 5089.3801 | 12214.5123 |

700 | 415.6320 | 1385.4424 | 2770.8847 | 4156.3271 | 5541.7694 | 6927.2118 | 16625.3082 |

800 | 542.8680 | 1809.5574 | 3619.1147 | 5428.6721 | 7238.2295 | 9047.7868 | 21714.6885 |

900 | 687.0660 | 2290.221 | 4580.4421 | 6870.6631 | 9160.8842 | 11451.1052 | 27482.6526 |

1000 | 848.2290 | 2827.4334 | 5654.8668 | 8482.3002 | 11309.7336 | 14137.1669 | 33929.2008 |

1200 | 1221.4500 | 4071.5041 | 8143.0082 | 12214.5122 | 16286.0163 | 20357.5204 | 48858.0489 |

1400 | 1662.5310 | 5541.7694 | 11083.5389 | 16625.3083 | 22167.0778 | 27708.8472 | 66501.2334 |

1600 | 2171.4690 | 7238.2295 | 14476.4589 | 21714.6884 | 28952.9179 | 36191.1474 | 86858.7537 |

1800 | 2748.2640 | 9160.8842 | 18321.7684 | 27482.6225 | 36643.5367 | 45804.4209 | 109930.6101 |

2000 | 3392.9190 | 11309.7336 | 22619.4671 | 33929.2007 | 45238.9342 | 56548.6678 | 135716.8026 |

2200 | 4105.4319 | 13684.7776 | 27369.5551 | 41054.3328 | 54739.1103 | 68423.8880 | 164217.3311 |

2400 | 4885.8033 | 16286.0163 | 32572.0326 | 48858.0490 | 65144.0652 | 81430.0816 | 195432.1957 |

STANDARD SPECIFICATION

Size | Pressure | L | C | H | K | A | D | |

mm | inch | MPa | mm | mm | mm | mm | mm | mm |

15 | 1/2’’ | 4.0 | 200 | 48 | 149 | 65 | 14 | 95 |

20 | 3/4’’ | 200 | 53 | 154 | 75 | 14 | 105 | |

25 | 1’’ | 200 | 58 | 159 | 85 | 14 | 115 | |

32 | 1 1/4’’ | 200 | 70 | 172 | 100 | 18 | 140 | |

40 | 1 1/2’’ | 200 | 75 | 189 | 110 | 18 | 150 | |

50 | 2 | 200 | 83 | 197 | 125 | 18 | 165 | |

65 | 2 1/2’’ | 200 | 93 | 220 | 145 | 18 | 185 | |

80 | 3’’ | 200 | 100 | 227 | 160 | 18 | 200 | |

100 | 4’’ | 1.6 | 250 | 118 | 257 | 180 | 18 | 220 |

125 | 5’’ | 250 | 135 | 289 | 210 | 18 | 250 | |

150 | 6’’ | 300 | 150 | 318 | 240 | 22 | 285 | |

200 | 8’’ | 1.0 | 350 | 170 | 379 | 295 | 22 | 340 |

250 | 10’’ | 450 | 203 | 429 | 350 | 22 | 395 | |

300 | 12’’ | 500 | 230 | 482 | 400 | 22 | 445 | |

350 | 14’’ | 550 | 260 | 534 | 460 | 22 | 505 | |

400 | 16’’ | 600 | 290 | 594 | 515 | 26 | 565 | |

450 | 18’’ | 600 | 320 | 649 | 565 | 26 | 615 | |

500 | 20’’ | 600 | 358 | 697 | 620 | 26 | 670 | |

600 | 24’’ | 600 | 420 | 799 | 725 | 30 | 780 | |

700 | 28’’ | 700 | 448 | 909 | 840 | 30 | 895 | |

800 | 32’’ | 800 | 508 | 1019 | 950 | 33 | 1015 | |

900 | 36’’ | 900 | 558 | 1119 | 1050 | 33 | 1115 | |

1000 | 40’’ | 0.6 | 1000 | 615 | 1199 | 1120 | 33 | 1175 |

1200 | 48’’ | 1200 | 728 | 1419 | 1340 | 33 | 1405 | |

1400 | 56’’ | 1400 | 815 | 1630 | 1560 | 35 | 1630 | |

1600 | 64’’ | 1600 | 915 | 1830 | 1760 | 35 | 1830 | |

1800 | 72’’ | 1800 | 1023 | 2040 | 1970 | 39 | 2045 | |

2000 | 80’’ | 2000 | 1133 | 2248 | 2180 | 42 | 2265 | |

2200 | 88’’ | 2200 | 1238 | 2453 | 2390 | 42 | 2475 | |

2400 | 96’’ | 2400 | 1343 | 2658 | 2600 | 42 | 2685 | |

MODEL SELECTION

AEMG - | □□□ | □ | □□ | □ | □ | □ | □ | □ | □ | □ | □ | □ | □ | □ |

[1] | [2] | [3] | [4] | [5] | [6] | [7] | [8] | [9] | [10] | [11] | [12] | [13] | [14] |

[1] | Nominal Diameter(mm)/ [inches] | [7] | Grounding and Lining Protection | |||||

002 | 032 [1¼] | 250 [10”] | 900 [36”] | -0 | Flange or body ground (10...2400) | |||

003 | 040 [1½] | 300 [12”] | 102 [40”] | -1 | Earth ring (10...250) | |||

004 | 050 [2”] | 350 [14”] | 122 [48”] | -2 | Ground electrode (25...2400) | |||

006 | 065 [2½] | 400 [16”] | 142 [56”] | -3 | Inlet protection ring (50...300) | |||

008 | 080 [3”] | 400 [16”] | 162 [64”] | [8] | Max. Process Temperature | |||

010 | 100 [4”] | 500 [20”] | 182 [72”] | A | ≤80℃ (All Linings) | |||

015 [½”] | 125 [5”] | 600 [24”] | 202 [80”] | B | ≤120℃ (PTFE、PFA、F46) | |||

020 [¾”] | 150 [6”] | 700 [28”] | 222 [88”] | C | ≤180℃ (PTFE、PFA) | |||

025[1’’] | 200 [8”] | 800 [32”] | 242 [96”] | [9] | Configuration - sensor/transmitter | |||

C | Compact (10...1000) | |||||||

[2] | Device Type | R | Remote (with 10m cable) | |||||

F | Flange | [10] | Environmental Protection Class | |||||

I | Insertion | 5 | IP65 | |||||

W | Wafer | 7 | IP67 | |||||

K | Clamp | 8 | IP68(Remote Type Only) | |||||

[3] | Flange Rating | [11] | Power Supply | |||||

06 | 0.6MPa (700...2400) | -A | (85-265)VAC/(45-63)Hz | |||||

10 | 1.0MPa (200...1200) | -D | (9-32)VDC | |||||

16 | 1.6MPa (10...600) | -B | 3.6VDC lithium battery | |||||

20 | ANSI 150 (15...600) | -C | 3.6VDC lithium battery +(85-265)VAC/(45-63)Hz | |||||

25 | 2.5MPa (10...600) | |||||||

40 | 4.0MPa (10...150) | -F | 3.6VDC lithium battery +(9-32)VDC | |||||

50 | ANSI 300 (15...600) | |||||||

99 | Special | [12] | Output and Input | |||||

[4] | Flange and Shell Material | B | Basic Configuration (current, pulse and contact outputs) | |||||

0 | Carbon steel | |||||||

4 | 304 Stainless Steel | M | Basic Configuration+MODBUS | |||||

6 | 316 Stainless Steel | H | Basic Configuration+HART | |||||

9 | Special | P | Basic Configuration+Profibus-DP | |||||

[5] | Lining Material | [13] | Calibration Specification | |||||

1 | Soft Neoprene (≤2400) | 1 | 3 point, 0.5% accuracy | |||||

2 | Hard Neoprene (≤2400) | 2 | 3 point, 0.2% accuracy | |||||

3 | PTFE (≤2400) | 3 | 5 point, 0.5% accuracy | |||||

4 | Polyurethane (≤300) | T | Other | |||||

5 | PFA (≤250) | [14] | Special Functions | |||||

6 | F46 (≤250) | /B | None | |||||

7 | Ceramics (≤250) | /T | Power off timer | |||||

8 | ETFE (≤600) | /Q | Quantitative control | |||||

9 | Nylon (≤2400,Insertion type only) | /H | Hourly accumulation | |||||

[6] | Electrode Material | /J | Relay output | |||||

1 | 316L Stainless Steel | /S | High frequency slurry | |||||

2 | Hastelloy C-22 | /G | GPRS | |||||

3 | Hastelloy B-10 | /N | NB-IoT | |||||

4 | titanium | /L | Ultra-low temperature | |||||

5 | tantalum | /P | Pressure sensor | |||||

6 | platinum/iridium Alloy | /K | RTD | |||||

7 | Tungsten Coated Stainless Steel | /C | Conductivity Sensor | |||||

8 | Ceramic | |||||||

E.G. | Ordering Code: AEMG-150F10011-0AC5-AM1/B | |||||||

A+K electromagnetic flowmeter; DN150, Flange type, 1.0MPa, Carbon steel flange and shell, Soft Neoprene lining, 316L stainless steel electrode; Flange grounding, Max. Process Temperaturee≤80℃, Compact–sensor/transmitter, Ingress Protection Class IP65; AC power supply, Basic configuration+MODBUS, 3 point, 0.5% accuracy. | ||||||||

Copyright © 2025 Keyontechs Co.,Ltd.